Engineering analysis is a critical process in engineering design, problem-solving, and decision-making. It involves applying mathematical, scientific, and computational methods to evaluate designs, predict performance, and optimize solutions in various engineering fields.

From structural analysis in civil engineering to thermal analysis in mechanical engineering, engineering analysis helps ensure safety, efficiency, and innovation in modern technology.

In this article, you’ll learn:

- What engineering analysis is and how it works

Key types of engineering analysis

Industries that rely on engineering analysis

The role of software tools in engineering analysis

Why engineering analysis is crucial for product development

Let’s dive into the importance, applications, and methods of engineering analysis!

What Is Engineering Analysis?

Engineering analysis is the systematic examination of engineering problems and designs using scientific principles, mathematics, and simulations. It helps engineers:

- Evaluate system performance before physical testing.

Identify potential failures and weaknesses in designs.

Optimize materials, costs, and efficiency in projects.

Ensure compliance with industry standards and regulations.

Example: In aerospace engineering, engineers use computational fluid dynamics (CFD) to analyze airflow over an aircraft wing before physical testing.

Key takeaway: Engineering analysis minimizes risks, reduces costs, and improves performance in engineering projects.

Key Types of Engineering Analysis

Engineering analysis can be classified into various categories based on industry and application.

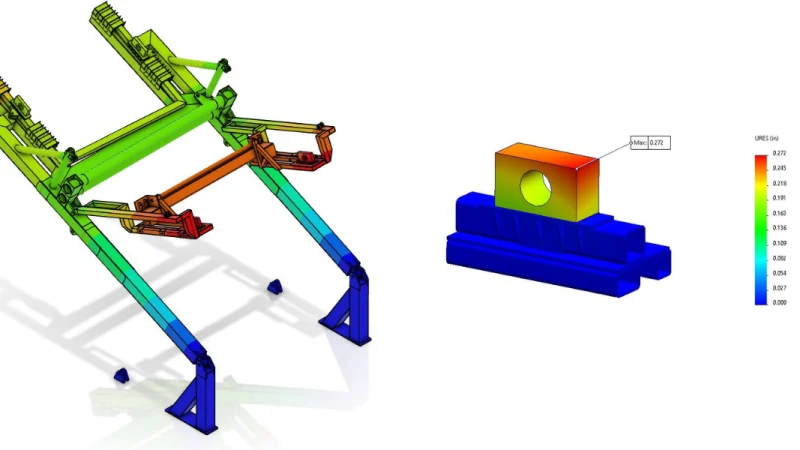

Structural Analysis

- Evaluates the strength, stability, and durability of structures.

Used in civil, mechanical, and aerospace engineering.

Techniques include finite element analysis (FEA) for stress testing.

Example: Analyzing a bridge’s load capacity to ensure it can support traffic and environmental forces.

Thermal Analysis

- Studies heat transfer, temperature distribution, and energy efficiency.

Critical in mechanical, chemical, and electrical engineering.

Methods include heat conduction, convection, and radiation analysis.

Example: Evaluating cooling systems in electronic devices to prevent overheating.

Fluid Dynamics Analysis

- Examines fluid flow behavior and pressure distribution in systems.

Used in automotive, aerospace, and HVAC industries.

Computational fluid dynamics (CFD simulations) are widely used.

Example: Designing fuel-efficient car aerodynamics to reduce drag and improve mileage.

Vibration and Modal Analysis

- Assesses resonance, vibrations, and dynamic performance of structures.

Applied in mechanical, civil, and aerospace engineering.

Ensures machinery and buildings withstand vibrations without failure.

Example: Testing a skyscraper’s ability to withstand earthquakes and wind forces.

Electrical and Circuit Analysis

- Evaluates circuit performance, power efficiency, and signal integrity.

Used in electrical, electronic, and telecommunication engineering.

Tools like SPICE simulation software help optimize circuits.

Example: Designing power distribution networks to improve efficiency in smart grids.

Importance of Engineering Analysis in Industries

Engineering analysis plays a vital role in various industries, ensuring safety, efficiency, and performance.

| Industry | Applications of Engineering Analysis |

| Aerospace | Aircraft design, aerodynamics, thermal protection |

| Automotive | Crash testing, engine performance, fuel efficiency |

| Civil Engineering | Structural stability, earthquake resistance |

| Electronics | PCB design, circuit analysis, power distribution |

| Energy | Renewable energy optimization, power plant efficiency |

| Manufacturing | Quality control, material testing, process simulation |

Key takeaway: Engineering analysis ensures that products, buildings, and systems function reliably and efficiently across industries.

The Role of Software in Engineering Analysis

Modern engineering relies heavily on computer-aided engineering (CAE) software to simulate, analyze, and optimize designs before production.

Popular Engineering Analysis Software

| Software | Application | Industry |

| ANSYS | Finite element analysis (FEA), thermal, fluid dynamics | Aerospace, automotive, energy |

| SolidWorks Simulation | Structural analysis, motion studies | Mechanical, manufacturing |

| MATLAB | Mathematical modeling, signal processing | Electrical, control systems |

| AutoCAD | Structural and architectural design | Civil engineering |

| COMSOL Multiphysics | Multiphysics simulation (thermal, fluid, electromagnetic) | Various engineering fields |

Example: Engineers use ANSYS to test bridge durability under extreme weather conditions before construction.

Tip: Learning engineering analysis software can significantly boost career opportunities in engineering fields.

How Engineering Analysis Improves Product Development

- Reduces Development Costs – Identifies design flaws early, avoiding costly rework.

Speeds Up Innovation – Enables rapid testing of multiple design concepts.

Enhances Safety & Reliability – Ensures products meet industry safety standards.

Optimizes Performance – Improves efficiency, durability, and sustainability.

Reduces Environmental Impact – Helps create energy-efficient and eco-friendly designs.

Example: In the automotive industry, engineering analysis is used to design lighter, fuel-efficient vehicles without compromising safety.

Tip: Engineering analysis is essential for sustainable and cost-effective product development.

Future Trends in Engineering Analysis

Artificial Intelligence (AI) & Machine Learning – AI-driven simulations for faster and more accurate analysis.

Sustainable Engineering – Green energy and eco-friendly material analysis.

Cloud-Based CAE Software – Remote collaboration and real-time simulations.

Quantum Computing in Engineering – Advanced simulations for complex calculations.

Future Insight: AI-powered engineering analysis can reduce testing time by up to 50%, accelerating innovation.

Tip: Stay updated with the latest engineering software and AI-driven analysis tools for career growth.

Conclusion

Engineering analysis is a fundamental process in engineering that ensures safety, efficiency, and innovation in modern technology. Whether it’s designing skyscrapers, optimizing renewable energy, or improving automotive safety, engineering analysis helps create better, stronger, and more reliable solutions.

Key Takeaways:

- Essential in all engineering fields – Structural, thermal, fluid, electrical, and more.

Reduces costs & risks – Detects design flaws before production.

Boosts efficiency & performance – Ensures products meet safety standards.

Relies on advanced software tools – ANSYS, MATLAB, SolidWorks, etc.

Future-driven by AI & sustainability – Engineering analysis is evolving rapidly!

Want to excel in engineering? Master engineering analysis tools and techniques for a future-proof career!

FAQs

1. What is the purpose of engineering analysis?

It helps evaluate designs, predict performance, and optimize engineering solutions.

2. What industries use engineering analysis?

Aerospace, automotive, civil engineering, electronics, energy, and manufacturing.

3. What are common engineering analysis techniques?

Finite element analysis (FEA), computational fluid dynamics (CFD), thermal analysis, and vibration analysis.

4. What is the difference between engineering design and engineering analysis?

Engineering design creates new solutions, while engineering analysis evaluates and optimizes them.

5. Which software is best for engineering analysis?

ANSYS, MATLAB, AutoCAD, SolidWorks Simulation, and COMSOL Multiphysics.

Also read: 7 Key Insights into the Edward Lowe Foundation Impact on Entrepreneurship