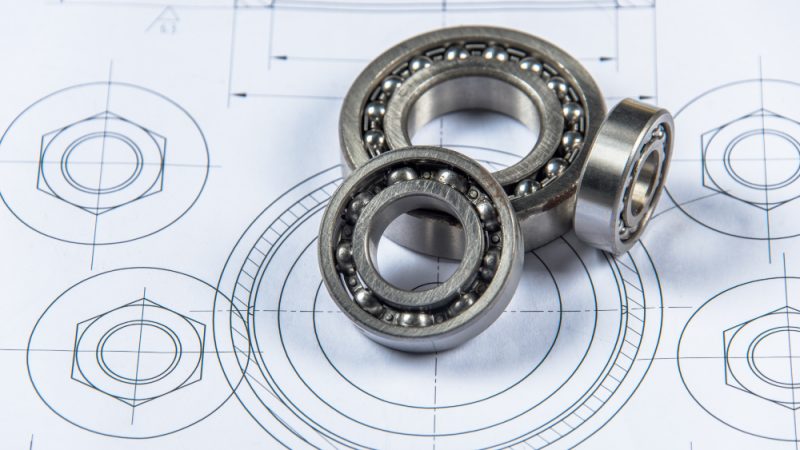

In the world of machinery and engineering, Ball Bearing Size Chart ball bearings are indispensable components, facilitating smooth rotation and reducing friction. Understanding ball bearing size charts is essential for selecting the right bearings for various applications. In this comprehensive guide, we’ll delve into ten essential tips to master ball bearing size charts, empowering you to make informed decisions and optimize performance.

Importance of Accurate Sizing: Ball Bearing Size Chart

Ball Bearing Size Chart Accurate sizing is crucial for optimal performance and longevity of machinery. A ball bearing that is too small may fail under heavy loads, while one that is too large can lead to excessive friction and premature wear. Referencing a comprehensive ball bearing size chart ensures precise selection based on application requirements.

Understanding Ball Bearing Size Chart Components:

Ball Bearing Size Chart A typical ball bearing size chart includes various parameters such as inner diameter (ID), outer diameter (OD), width, and tolerance class. Familiarizing yourself with these components is the first step towards mastery. Each parameter plays a vital role in determining the suitability of a bearing for specific applications.

Measurement Units: Inches vs. Millimeters:

Ball bearing size charts may present dimensions in either inches or millimeters. While inches are commonly used in some regions, millimeters are preferred in most industrial applications due to their precision and international standardization. Understanding both units is essential for interpreting size charts accurately.

Inner and Outer Diameter Considerations:

Ball Bearing Size Chart The inner diameter (ID) and outer diameter (OD) of a ball bearing dictate its fit within a shaft or housing. Proper alignment between the bearing and its mating components is critical for efficient operation. Ensure compatibility by selecting bearings with ID and OD dimensions that match the shaft and housing specifications.

Width and Thickness Metrics:

Ball Bearing Size Chart The width and thickness of a ball bearing determine its load-bearing capacity and stability. Bearings with greater width can support higher loads but may require larger housings. Conversely, thinner bearings are suitable for space-constrained applications but may have lower load capacities. Consider both factors when referencing size charts.

Load Ratings: Dynamic and Static:

Dynamic and static load ratings indicate the maximum loads a bearing can withstand during operation and at rest, respectively. Exceeding these ratings can lead to premature failure and safety hazards. Consult the ball bearing size chart to ensure that the selected bearing can accommodate the anticipated loads in your application.

Choosing the Right Tolerance Class:

Tolerance class defines the allowable deviation in dimensions for a ball bearing. Higher tolerance classes offer tighter dimensional control but may come at a higher cost. Selecting the appropriate tolerance class based on application requirements and budget constraints is crucial for achieving desired performance levels.

Lubrication and Temperature Factors:

Proper lubrication is essential for reducing friction and extending the service life of ball bearings. Consider the operating temperature range and environmental conditions when selecting lubricants. Consult the size chart for recommendations on lubrication type and intervals to maintain optimal performance in diverse operating conditions.

Application-Specific Considerations:

Each application has unique requirements and operating conditions that influence bearing selection. Factors such as speed, load type, misalignment, and contamination levels must be carefully evaluated. Referencing the ball bearing size chart in conjunction with application-specific guidelines ensures compatibility and reliability.

Utilizing Online Resources and Tools:

In the digital age, online resources and tools provide invaluable assistance in mastering ball bearing size charts. Manufacturers’ websites, engineering forums, and software applications offer interactive sizing calculators, 3D models, and technical support. Leverage these resources to streamline the selection process and enhance your understanding of ball bearing specifications.

Conclusion:

Mastering ball bearing size charts is essential for engineers, technicians, and enthusiasts involved in machinery design and maintenance. By following the ten essential tips outlined in this guide, you can gain confidence in interpreting size charts accurately and selecting the right bearings for diverse applications. Empower yourself with knowledge and elevate your expertise in ball bearing technology for enhanced performance and reliability.

FAQs:

Q1: How do I determine the appropriate ball bearing size for my application?

A1: Consult a ball bearing size chart and consider factors such as load, speed, dimensions, and operating conditions to select the most suitable bearing.

Q2: What is the significance of tolerance class in ball bearing selection?

A2: Tolerance class defines the allowable deviation in dimensions for a bearing. Choosing the right tolerance class ensures proper fit and functionality in the intended application.

Q3: Can I interchange bearings with different tolerance classes?

A3: Interchanging bearings with different tolerance classes may affect performance and reliability. It’s recommended to adhere to manufacturer specifications for optimal results.

Q4: How do I interpret dynamic and static load ratings in a ball bearing size chart?

A4: Dynamic load rating indicates the maximum load a bearing can withstand during operation, while static load rating refers to the maximum load at rest. Ensure that the selected bearing exceeds the anticipated loads in your application.

Q5: Where can I find additional resources for mastering ball bearing size charts?

A5: Online resources such as manufacturer websites, engineering forums, and software applications offer valuable tools and support for interpreting size charts and selecting the right bearings. Explore these resources to enhance your expertise in ball bearing technology.

Also read : SAM RUBIN’S TOP 10 STRATEGIES FOR SUCCESS IN MARKETING